Fire detection system - leak testing made easy

De groot installatiegroep B.V.

Efficient leak testing of connections with minimal waste

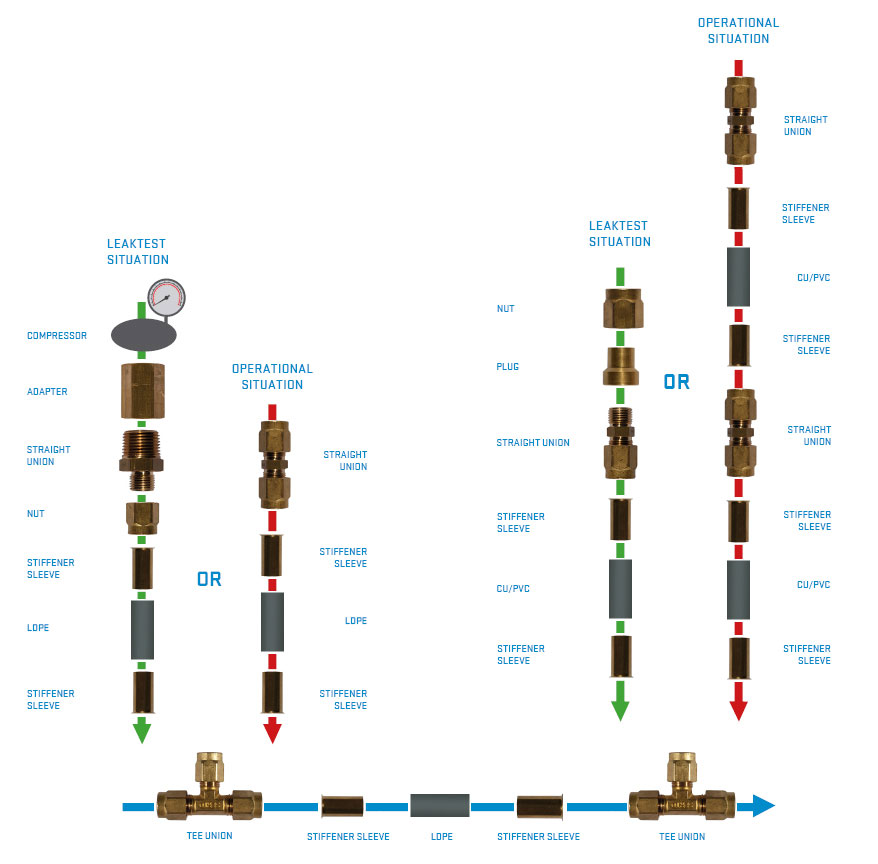

De Groot Installatiegroep designed a fire detection system. The fire detection system is based on the principle that when a fire occurs, the tubing will melt, crack and leak. As a result of the leaking of the tubing, the pressure will drop, and the fire is detected. De Groot Installatiegroep has the system divided into several segments so they can be tested for leaks separately. To test this system in a relatively simple way without the need to replace the couplings after the test De Groot was looking for an easy-to-apply solution. Teesing advised on the best and easiest option.

The tubing in this application is made of CU/PVC and LDPE. The LDPE tube is the one that indicates the fire by melting. To connect the tubing and the various segments, as well as connecting it to the compressing unit, Serto brass couplings are used.

The solution

In this application the use of Serto couplings is ideal for their ease of mounting/dismounting. Initial assembly of the couplings is done in the conventional manner. The couplings are tightened by hand and the nut is tightened 1 3/4 turns with a wrench so the coupling is leakproof. These couplings can be disconnected and a new pre-assembled nut and ferrule can be installed. The couplings just needs a simple 1/4 turn to be leaktight and there is no need for Teflon tape or O-rings.

This method provides ease of installation, time savings and above all, material savings.

More information?

More information about our products or looking for a custom solution?

Please contact our Sales Engineers.

NL: +31 70 413 07 00

CN: +86-(0)10-60576210

USA: +(1) 973 383 0691

TW: +886-(0)3-5600560

Already know who you're dealing with? Contact your salesperson directly:

Look up salesperson

WE MAKE YOUR TECHNOLOGY WORK

NL - Tel. +31 70 413 07 50

USA - Tel. +(1) 973 383 0691

CN - Tel. +86 (10) 56865822/56865835

TW - Tel. +886-(0)3-5600560