Teesing develops laminar flow restriction

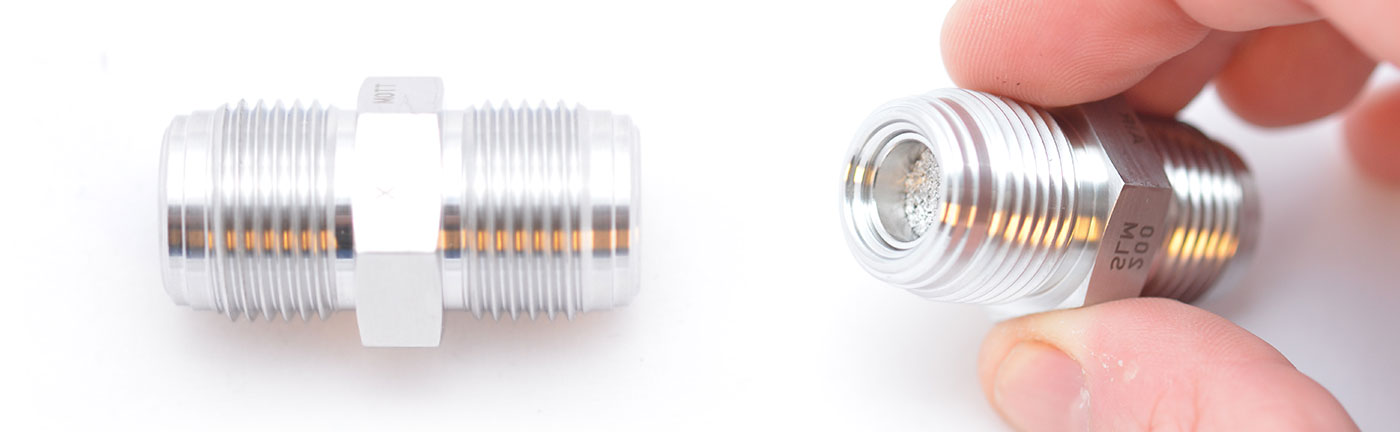

Porous metal elements can be integrated into all kinds of fittings for a cost effective solution that guarantee laminar flow in your processes.

By combining two existing products into one, a completely new product was created. How did our engineering department come up with this innovation? It all evolved by a question of one of our customers in the Semiconductor industry already using our fittings. The challenge was to make a cost effective flow restriction in their system with a minimum of change in the current design. This can be done in two ways:

Using a component with an orifice. Restriction by a hole in the house of the fitting.

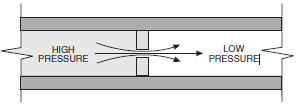

Standard Orifice:

Speed, pressure and heat increase as gas moves through the orifice, causing wear and tear.

Using a flow restrictor from with a porous metal element

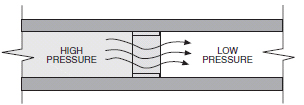

Flow Restrictor:

Gas moves uniformly through porous metal element with minimal friction due to viscosity.

Teesing created a solution for this particular customer by combining an existing fitting with a porous metal element inside to create a laminar flow.

Major advantages

- Reduces the flow burden - from one pore to hundreds

- Prevents plugging - by distributing flow over the entire insert.

- Minimum change of design – same coupling, different functionality.

To identify the best design for your application, it is essential to make sure you know the following parameters:

- Type of gas

- Upstream pressure

- Downstream pressure

- Desired flow rate (positive pressure, ATM or vacuum)

- Fitting (if applicable) a. Type b. Size c. Material

If you want a cost effective solution with optimum laminar flow in your process a porous metal element is the best solution.

Of course this integration of a porous metal element into a fiting can be done with any fitting!

Contact us for more information.

Any Questions?

More information about our products, services or looking for a custom solution?

Please contact our Sales Engineers.

WE MAKE YOUR TECHNOLOGY WORK

NL - Tel. +31 70 413 07 50

USA - Tel. +(1) 973 383 0691

CN - Tel. +86 (10) 56865822/56865835

TW - Tel. +886-(0)3-5600560